4 stroke engine parts and working

Working of 4 stroke engine:

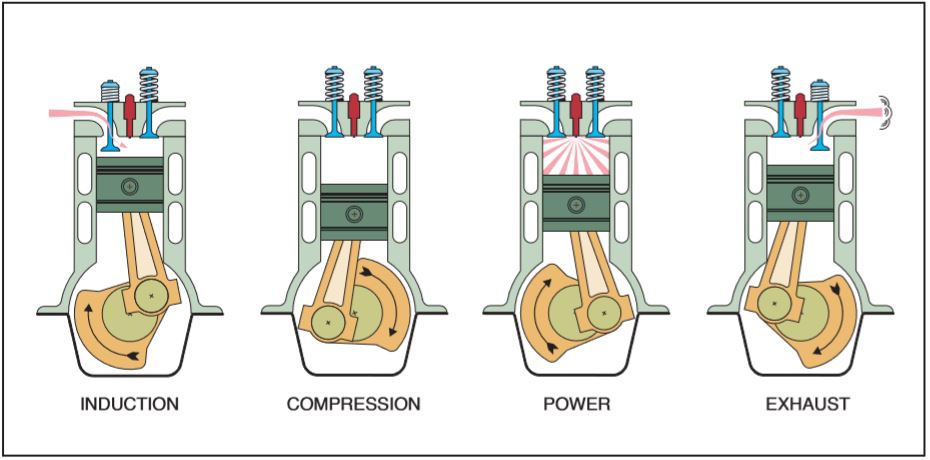

The engine acts to transform thermal power into electrical energy. 4- Stroke engine is works in four stages, i.e. Power, induction, compression, and exhaust. Both these steps fulfill one cycle of the engine.

Another strong casting called the cylinder head covers the top of the cylinder. Tunnels in the cylinder head, operated by valves, allow air and exhaust gas to flow in or out of the cylinder.

The cylinder’s bottom is formed by a piston, another machined metal casting built to travel up and down inside the cylinder, with springy metal piston rings creating an almost gas tight seal between the piston and the cylinder walls. For the moment, don’t think about how we get a mixture of fuel and air to burn inside the cylinder: just agree that as it burns it creates a mixture of water vapor, carbon dioxide and small amounts of some more unpleasant gasses like sulfur dioxide and nitrogen oxides.

The rise in temperature allows this gaseous mixture to expand – raise the pressure inside the cylinder and drive down the piston. The piston is connected to a connecting rod ,other end of which is attached to the crankshaft. Just as a bicycle’s cranks turn the vertical movement of the rider’s legs into a spinning movement of the wheels, the crankshaft converts the downward movement

One end of the crankshaft is holding a flywheel of heavy metal. Once the flywheel starts turning, the momentum keeps it going, so the crankshaft continues to turn with it – driving the piston back up the cylinder. As it does, one of the valves in the head of the cylinder opens so that the exhaust gasses can escape.

The still-spinning flywheel and crankshaft drag it back down again as soon as the piston reaches the top of its journey. The exhaust valve shuts down at this point and the inlet valve opens, allowing fresh air to flood into the cylinder’s expanding space.

This time, the inlet valve opens as the piston reaches the bottom of its stroke. The air inside the cylinder is compressed with both valves shut down and the force of the flywheel pushing the piston back up again.

It gets hot if you compress some gas. By putting your finger over the outlet hole of a bicycle pump and pumping the handle, you can feel the effect on yourself. Even after several hits, a bicycle pump can barely develop more than 100 psi, but the pressure inside the cylinder of a diesel engine rises to more than 500 psi in less than 1/100 seconds. Its temperature rises, as a result, to something in the order of 800°C.

Diesel fuel doesn’t burn quickly under normal conditions, but it will combust spontaneously if you spray a fine mist of it into hot pressurized air. The fuel system of the engine is designed to do just this – to generate the burning mixture of air and fuel in the cylinder that is required to repeat the process.

So at last, the basic operating cycle of a diesel engine, made up of four distinct strokes of the piston called Induction, Compression, Power and Exhaust.