Sand mold casting | Explained

Sand casting is type of casting in which sand mold is used to produce castings. This is most widely used type of casting. Around 60 percent of casting produced in industry are through sand casting.Sand casting is performed in a setup called foundry. Usually this is most cheap type of casting.

Sand being high refractory material finds application in various metal casting. Different bindings agents are used according to application to retain the shape of pattern and to obtain moisture water is used but sometimes other substances are also used.

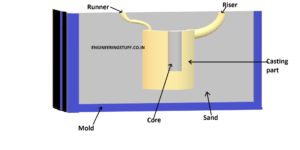

Process of sand mold casting is very simple and before understanding that we have to go through few terms as given below:

- Pattern

- Mold

- Core

- Runner

- Riser

- Gates

Pattern: Patterns are basically replica of the final product. They are generally made up of woods or plastics. Pattern have size slightly higher than the final product to compensate the contraction of metal during solidification.shape and size of final product will depend totally upon pattern. Strength of pattern should be such that it withstands the compacting loads.

Mold: Mold is a box filled with sand having cavity of finished part. Pattern is placed in mold box and rest of area is filled with sand. Mold is basically in two pieces called as upper and lower mold.

Core: Suppose we have a part to cast which is hollow from inside and core is a component which finds its application here. When mold is made using pattern and sand, a core is hung at place where we don’t need cast metal.

So core is a component which is used to produce internal cavities. Its function is same as that of pattern. Cores are disposable or breakable in order to get them out of parts.

Runner: Runner is entry point of molten metal. When molten metal is taken out of furnace, route through which it is poured into mold is called runner. Runner flow molten metal to every corner of mold.

Riser: Risers are second opening point of mold. When metal is poured into mold its entry point is runner while its exit or reserve point is riser. Function of riser is to keep the reserve of molten metal to fill the space contracted due to shrinkage.

Gates: Gates are the link between runner and cast area. Metal flows to cast part area from runner to final part.

Casting Process :

1.Pattern of desired shape is made.

2.Pattern is places in to mold box.

3.Sand is prepared with binders and moisture.

4.Sand is filled in mold box and compacted enough so it retains its shape.

5.Pattern is remove from mold.

6.If mold is in two pieces upper cover is place at this stage.

7.If internal cavity is required in part a core is made of desired shape.

8.Core is hung in its place.

9.Molten metal from furnace is brought near and slowly poured into mold through runner.

10.When molten metal comes out of riser pouring is stopped.

11.Metal is allowed to cool and when cooled completely removed from mold.

12.Surface of finished part is cleaned.

To know casting defects click here