What is a hob and what is hobbing process?

Hobbing is a process of manufacturing different type of gears, splines and sprockets using a special tool called Hob and a machine on which this process is performed is called Hobbing machine. Hobbing operation is a type of milling machine as it has same working principle.

This is widely used gearing manufacturing process and occupies maxing volume of industry. In terms of cost of manufacturing ,hobbing is a expensive process but comparing it with manufacturing speed, versatility and quality it find its place.

Hobbing can produce following type of gear:

- Spur gears

- Worm gears

- Sprockets

- Helical gears

- External splines

- Involute gears

- Cycloid gears

What is hobbing machine and hobbing process?

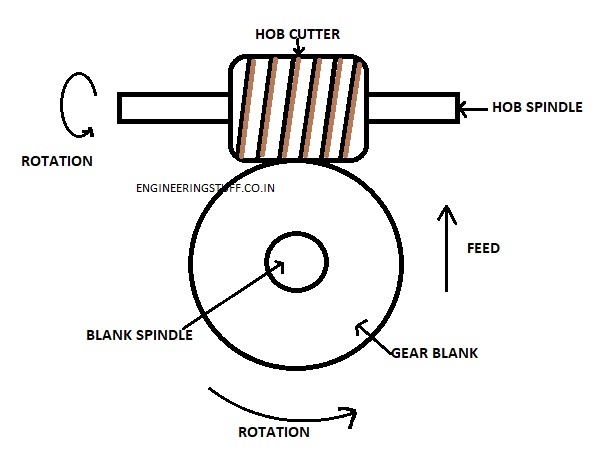

Hobbing machines are generally numerically controlled with a computer program.These machine comes in different sizes and are motor driven with three phase electric supply. It has setup of two rotating spindles out of which one carries the hob cutter while other one carries the gear blank.

Rotating speed and axis of both the spindles are variable which is provided to produce different type of gears. Other than rotating speed and axis variation, Spindles can move axially as well as across axis. This whole setup allows wide range of manufacturing possibilities.

If a spur gear is to be made, the hob cutter spindle is set at angle equal to its lead angle and if helical gear is to be made same angle in increased equal to required angle in helical gear. Speed of both the spindles decides the number of teeth on gear blank.

For a single cutter hob, number of teeth produced on the gear blank is equal to the speed ratio between hob and blank spindles. When all parameter of machine are set, both spindles are rotated while any of the spindle being fed against other until final shape of gear teeth is obtained on gear blank.

What is a Hob?

Hob is cylindrical in shape and has series of teeth arranged in helical order. These teeth when fed against gear blank results in gear teeth forming. Hob comes in different module, diameter, accuracy and material range and is selected based specs of gear to be produces.

There are different type of hobs like Involute spine hob, single thread involute hob, worm gear hob, sprocket hob, straight key spline hob and shank hobs. If a single teeth of hob is cut cross section-ally its shape is almost same as the teeth of gear will produce on gear blank.